description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Product Description

Description

Steel C / U post is common in Mexico, Uruguay, Bolivia, Chile, etc.

This C/U Post Roll Forming Machine can be designed for thickness 4-6mm, it is widely used as post of guardrail. We use forged iron stands(see picture) and gearbox driving to make sure this machine can work long in a stable situation.

Technological process

Decoiler—Feeding&Leveling—Punching—Roll forming—Hydraulic cutting—Output tables

This C/U Post Roll Forming Machine can be designed for thickness 4-6mm, it is widely used as post of guardrail. We use forged iron stands(see picture) and gearbox driving to make sure this machine can work long in a stable situation.

Technological process

Decoiler—Feeding&Leveling—Punching—Roll forming—Hydraulic cutting—Output tables

Technical Data

Parameters:

1.Suitable Material: Hot Rolled Steel

2.Material Thickness: 4 – 5 mm

3.Line speed: 0-8 m / min

Components:

The C/U Post Highway Guardrail Roll Forming Machine is mainly made up of the following parts.

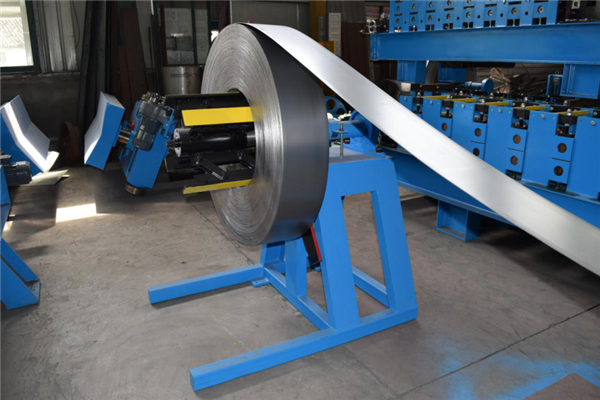

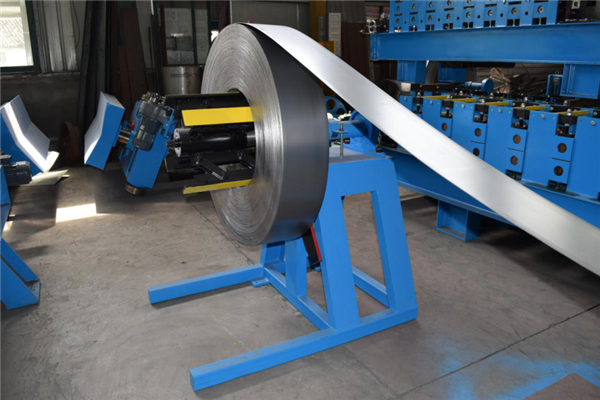

1.Un-coiler(Manual/Hydraulic)

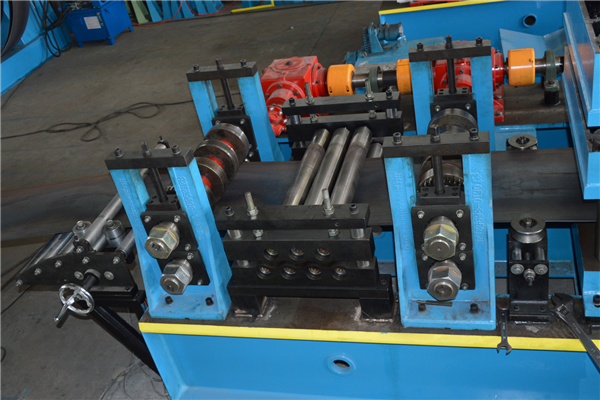

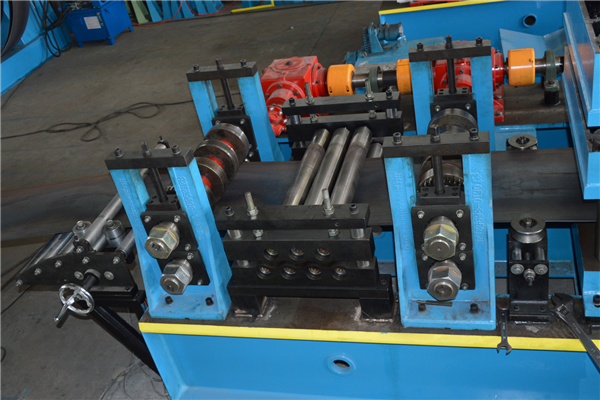

2.Feeding and straightening device

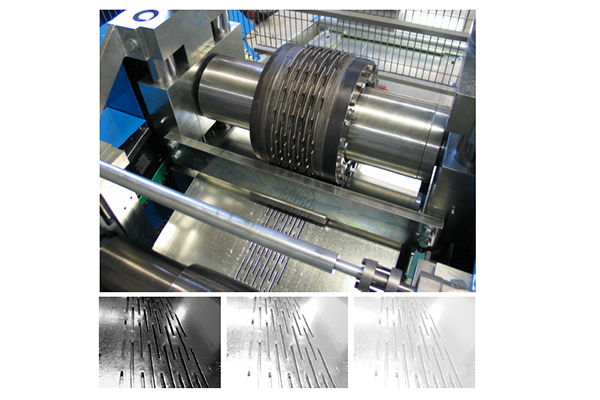

3.Hydraulic punching

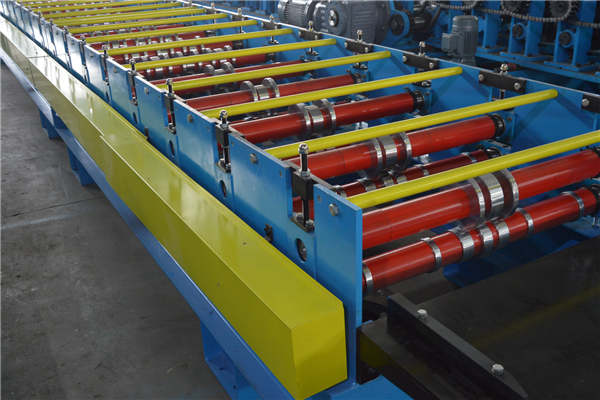

4.Roll forming unit

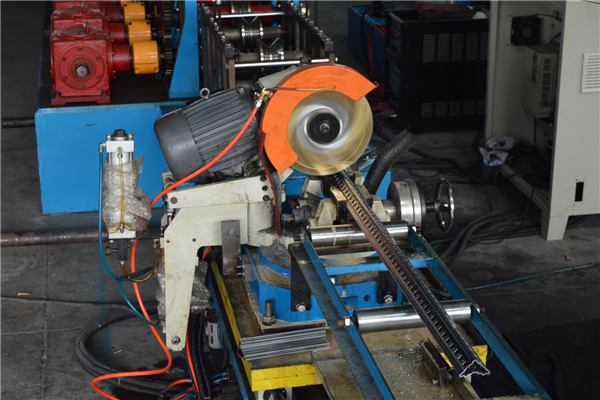

5.Hydraulic cutting device

6.PLC control box with touch screen

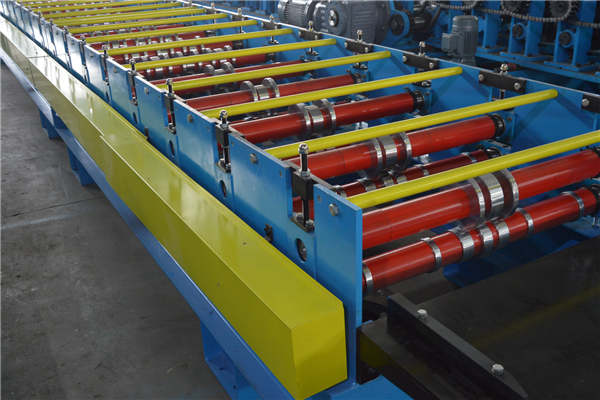

7.Receiving table

1.Suitable Material: Hot Rolled Steel

2.Material Thickness: 4 – 5 mm

3.Line speed: 0-8 m / min

Components:

The C/U Post Highway Guardrail Roll Forming Machine is mainly made up of the following parts.

1.Un-coiler(Manual/Hydraulic)

2.Feeding and straightening device

3.Hydraulic punching

4.Roll forming unit

5.Hydraulic cutting device

6.PLC control box with touch screen

7.Receiving table

Application

The C barrier post or U post as a support for the beam guardrail and usually determines the performance of the guardrail during the collision. Proper installation of the guardrail post will maximize the performance of the guardrail. The barrier post has a long service life and the surface is usually hot-dip galvanized or spray-coated to provide rust and corrosion resistance.

The steel C post both with and without flanges, which are differentiated according to your intended application. Usually, the pillars without flanges are mostly fixed to the soft soil by the pillars. But if you want to fix it on a concrete pavement, the pillar with steel plate is the best choice for your installation: just use long bolts to secure the pillar to the position you want.

The steel C post both with and without flanges, which are differentiated according to your intended application. Usually, the pillars without flanges are mostly fixed to the soft soil by the pillars. But if you want to fix it on a concrete pavement, the pillar with steel plate is the best choice for your installation: just use long bolts to secure the pillar to the position you want.

Profile Drawing

Optional Configuration

-

Decoiler

-

Manual Decoiler

-

Hydraulic Decoiler

-

Double Head Decoiler

-

-

Feeding

-

Leveler

-

Servo Feeder

-

-

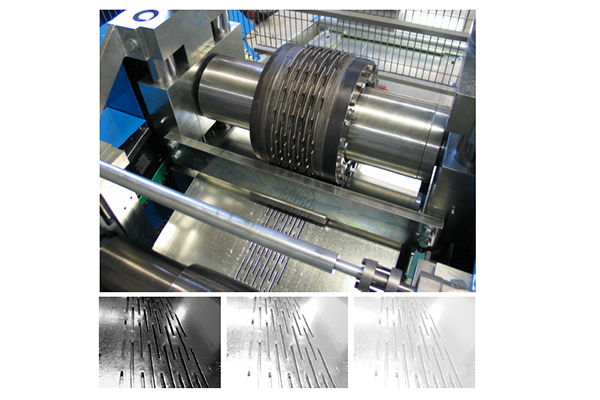

Punching

-

Punching Press

-

Hydraulic Punching Station

-

Rotary Punch

-

-

Stands

-

Wall Plate

-

Casting Iron

-

Guide Post

-

-

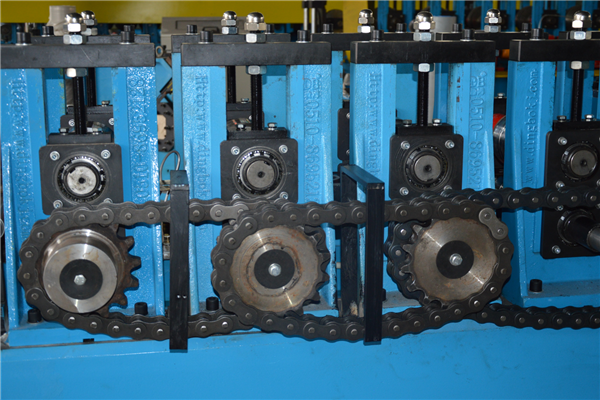

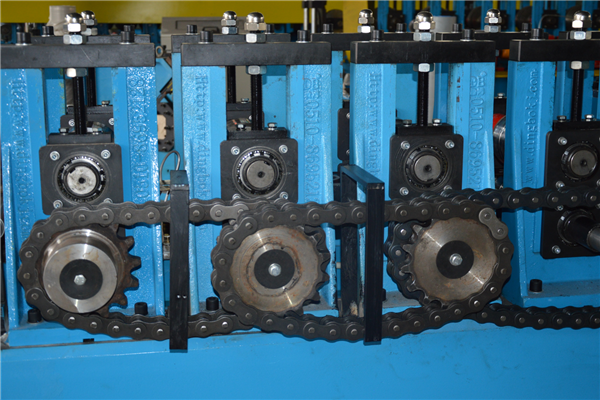

Driving

-

Chain Drive

-

Gearbox Drive

-

Gearbox Drive With Coupling

-

-

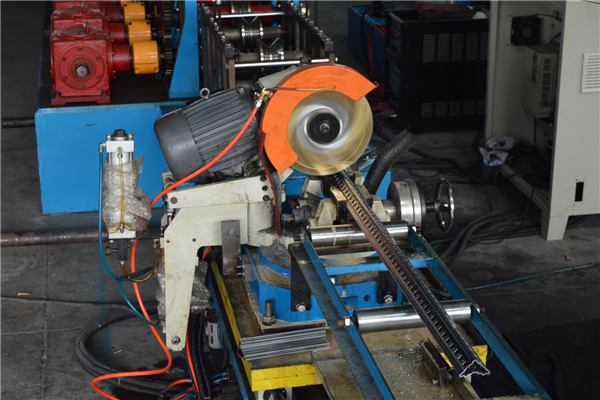

Cutting

-

Saw Cutting

-

Fast Flying Cutting

-

-

Out Table

-

Non-Powered

-

Auto-Stacker

-