This welded machine line is specially used for producingΦ19-Φ76mm, δ0.5-2.5mm high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe(δ≤2mm).

The composition of equipment is from uncoiler to fixed length cutting saw.

Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

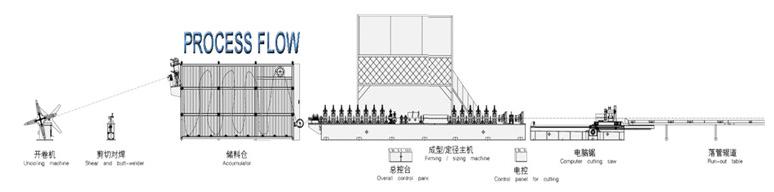

Working Flow

Slit Coil — Un-Coiler — Shearing And Butter Welder — Storage/ Accumulator — Forming — Welding — Cooling — Sizing — Cutting Saw — Run Out Table — Finishing — Pipe Collecting and Packaging

1.Pipe O.D(round): 19-76mm

2.Square pipe: 16*16-60*60mm

3.Thickness: 0.5-2.5mm

4.Length: 4-12m

5.Speed: 20-100m/min

6.Main motor: 80KW

7.H.F welder: 150Kw

8.Maximum coil weight:≤2500kg

9.Dimension of machine:40M*5M(L*W)

Machine Components

1. Decoiler

2. Shear and butter welder

3. Accumulator

4. Straighener

5. Forming machine

6. Welder and cleaner

7. Cooler

8. Size mill

9. Flying saw cutter

10.Run out table

11.Pneumatic system

12.Electrical control

|

Unit power standard |

380V / 22V; 50HZ; three-phase four-wire system |

|

|

Unit power |

high frequency |

150 KW |

|

Main motor |

80 KW |

|

|

Unit area |

45M×5M(L*W) |

|

|

High-frequency room volume |

5M×4M×2.8M |

|

|

Water source |

cooling pool 30m³ / 1 set high-pressure pump |

|

|

Air source |

1 set Air compressor |

|

|

Required lifting equipment |

Two 10-ton cranes |

|

|

Conventional consumables |

|

|