description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Product Description

Description

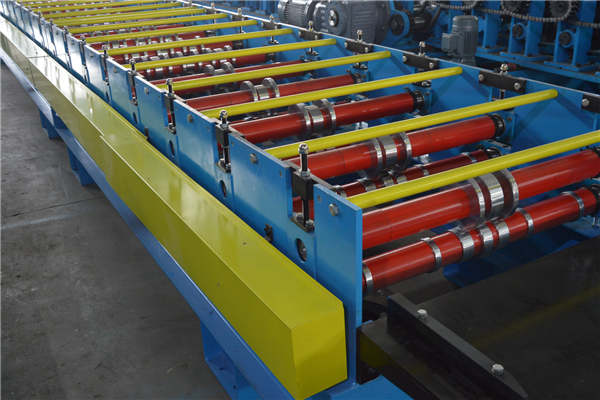

This C/Z Quick Interchangeable Roll Forming Machine adopts a special structure. The rollers for C&Z are changed very quickly without dismantle any parts . One machine can produce all specifications of C/Z/U purlins. Crimples are optional to increase rigidity of purlins. The width of the purlins can be automatically adjusted by PLC. If you need more economy solution then can be Handle Wheel adjusting as well. This machine we adopt pre-punching and pre-cutting or post-cutting system.

We have two solutions for you:

a) Fully automatic type: purlin size change and CZ interchange both are controlled by PLC and operating on touch panel, within 1 minute.

b) Semi-automatic type: purlin size change by press button, CZ interchange change manully (within 10 minutes)

We have two solutions for you:

a) Fully automatic type: purlin size change and CZ interchange both are controlled by PLC and operating on touch panel, within 1 minute.

b) Semi-automatic type: purlin size change by press button, CZ interchange change manully (within 10 minutes)

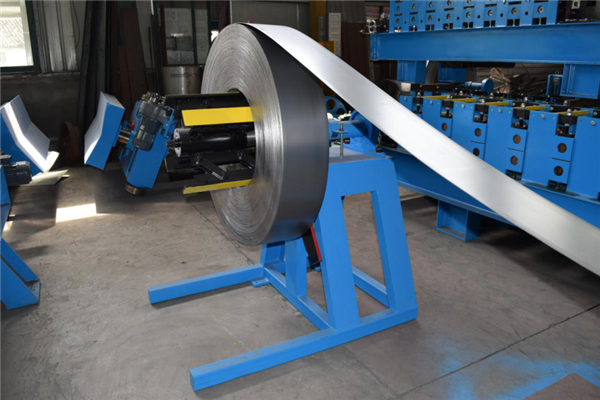

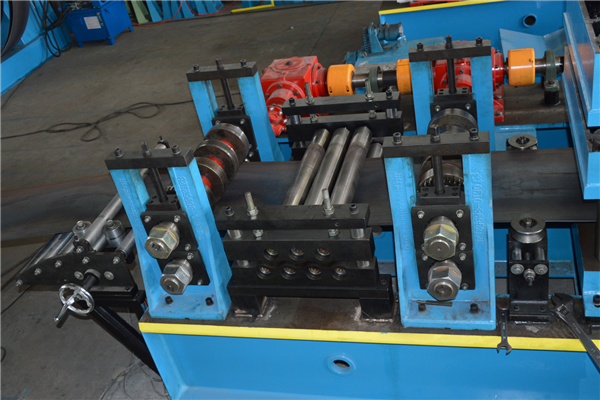

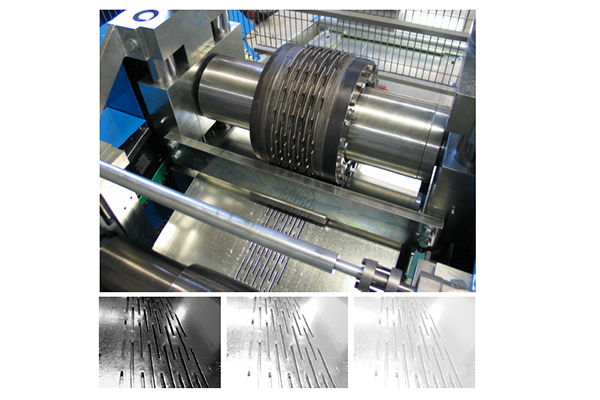

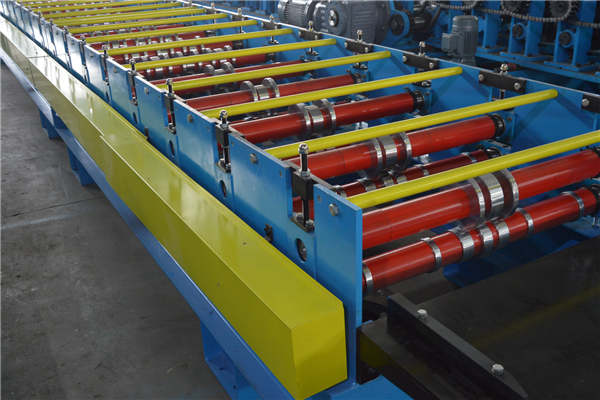

Machine Picture

Technical Data

1 General

1.The machine is able to produce both C and Z purlins for various sizes, easy operation, and high efficiency.

2.Speed: Max. 25m/min (not including cutting and punching)

3.Main machine size: about 9600 x 1500 x 2000mm

4.Weight: about 12T

5.Voltage: 380V, 3P, 50 Hz(Customized)

2 Raw Material

1.Material type: hot rolled coil, galvanized coil.

2.Yield strength: 235Mpa, 345Mpa, 350 Mpa

3.Thickness:1.5-3.0mm

1.The machine is able to produce both C and Z purlins for various sizes, easy operation, and high efficiency.

2.Speed: Max. 25m/min (not including cutting and punching)

3.Main machine size: about 9600 x 1500 x 2000mm

4.Weight: about 12T

5.Voltage: 380V, 3P, 50 Hz(Customized)

2 Raw Material

1.Material type: hot rolled coil, galvanized coil.

2.Yield strength: 235Mpa, 345Mpa, 350 Mpa

3.Thickness:1.5-3.0mm

Application

A c purlin or z purlin is a horizontal beam or bar to provide structural support in buildings. Our purlin roll former can produce purlins of different sizes. C Z purlin Roll Forming Machine is also called Interchangeable purlin roll forming machine or z purlin making machine. In steel construction, the term purlin typically refers to roof framing members that span parallel to the building eave and support the roof decking or sheeting. The steel of c purlins are in turn supported by rafters or walls. So pre-punched purlins are quick to install and suitable for both insulated and uninsulated roofs and walls. The thickness and height of the purlin selected depend on span length and loads.

Profile Drawing

Standard Shape Profile (also can be customized)

C purlin: A=100-300mm; B=40-80mm; C=10-25mm; T=1.5-3mm

Z purlin: A=120-300mm; B=40-80mm; C=10-25mm; T=1.5-3mm

C purlin: A=100-300mm; B=40-80mm; C=10-25mm; T=1.5-3mm

Z purlin: A=120-300mm; B=40-80mm; C=10-25mm; T=1.5-3mm

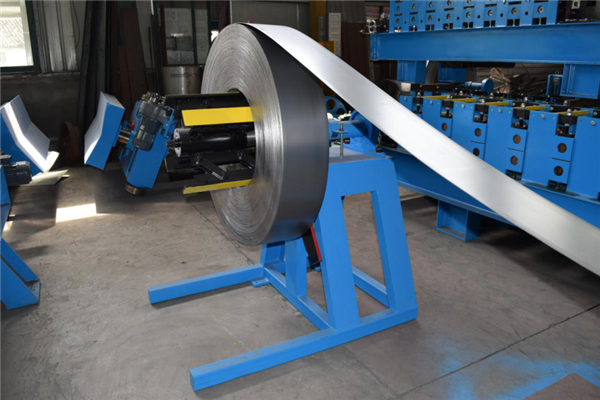

Optional Configuration

-

Decoiler

-

Manual Decoiler

-

Hydraulic Decoiler

-

Double Head Decoiler

-

-

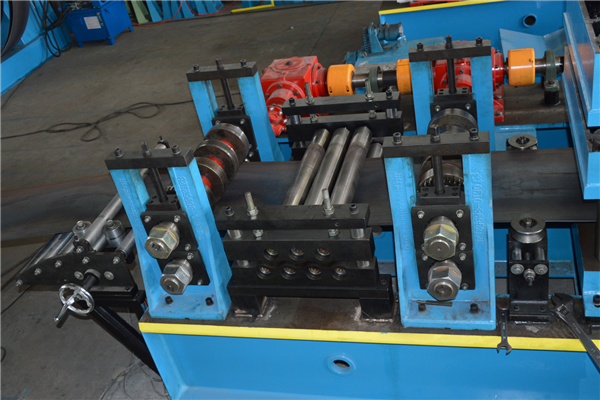

Feeding

-

Leveler

-

Servo Feeder

-

-

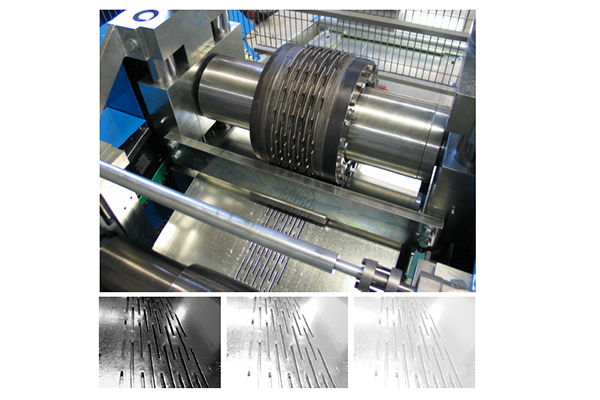

Punching

-

Punching Press

-

Hydraulic Punching Station

-

Rotary Punch

-

-

Stands

-

Wall Plate

-

Casting Iron

-

Guide Post

-

-

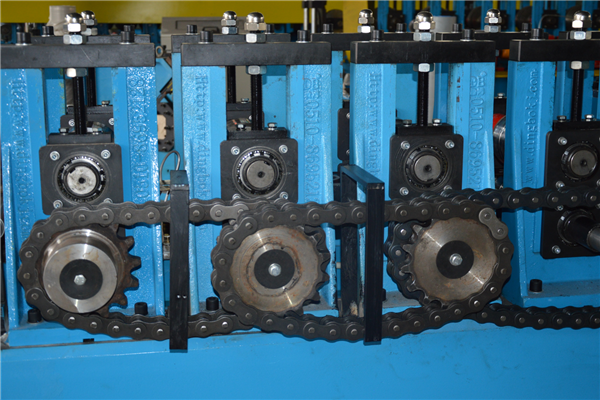

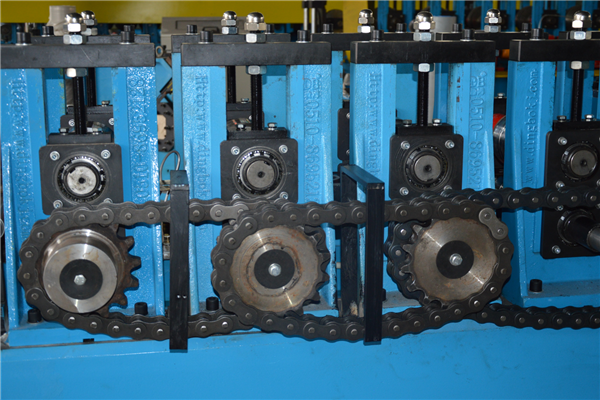

Driving

-

Chain Drive

-

Gearbox Drive

-

Gearbox Drive With Coupling

-

-

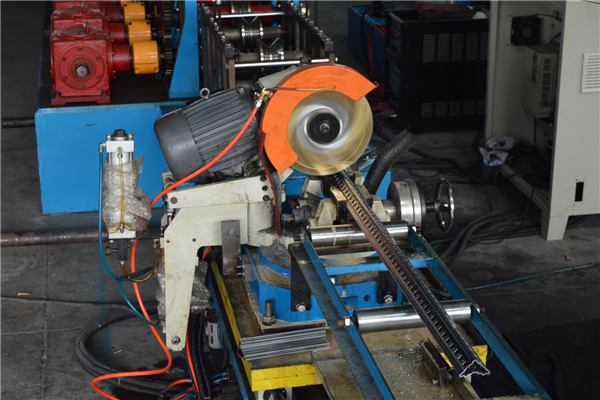

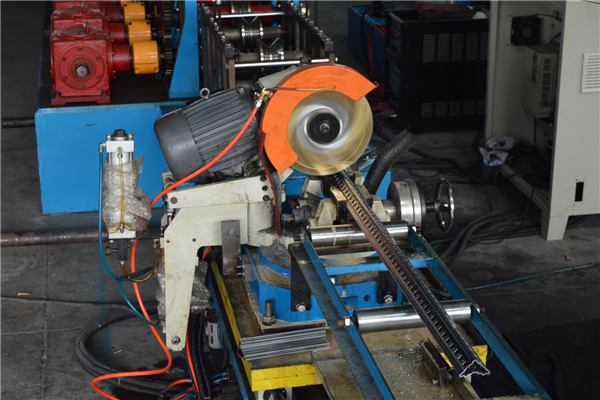

Cutting

-

Saw Cutting

-

Fast Flying Cutting

-

-

Out Table

-

Non-Powered

-

Auto-Stacker

-