The Door Frame Roll Forming Machine include Roman Column Roll Forming Machine, Curved Door Frame Roll Forming Machine, Straight Door Frame Roll Forming Machine, Door Plank Roll Forming Machine etc. We offer any kinds of door frame roll forming machines according to your profile drawing.

|

Door Frame roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

|

|

Thickness(mm):1.0-2.0 |

|

|

|

|

Yield strength: 250 - 550MPa |

|

|

|

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|

|

2 |

Nominal forming speed(m/min) |

10-20m/min |

Or according to your requirement |

|

3 |

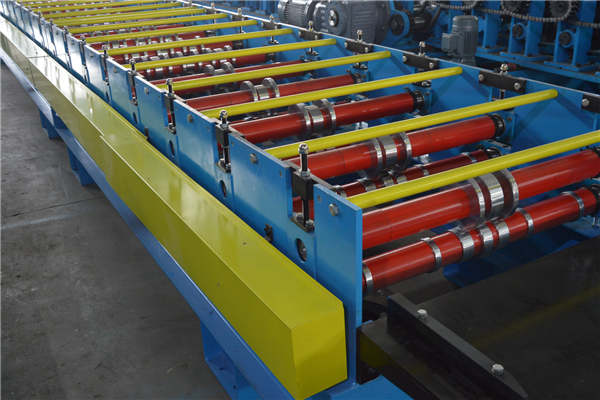

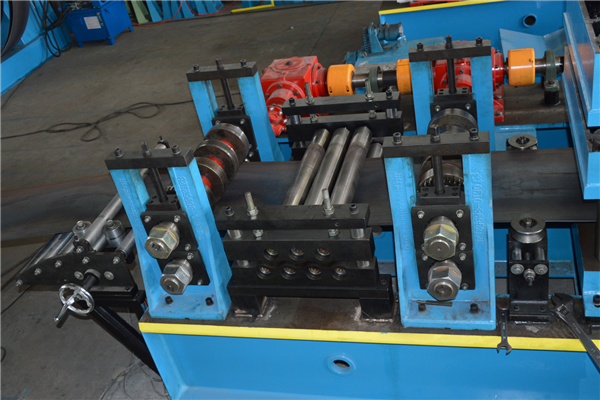

Forming station |

16 |

According to your profile |

|

4 |

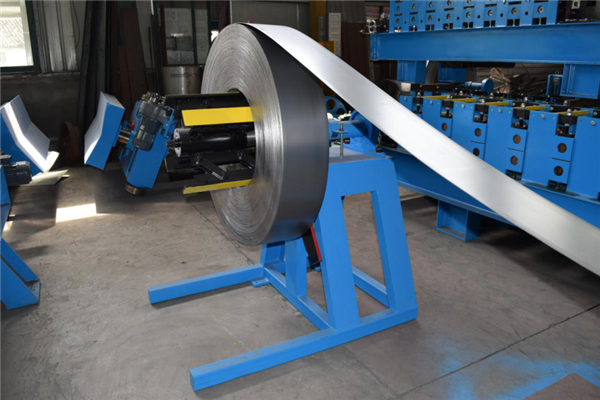

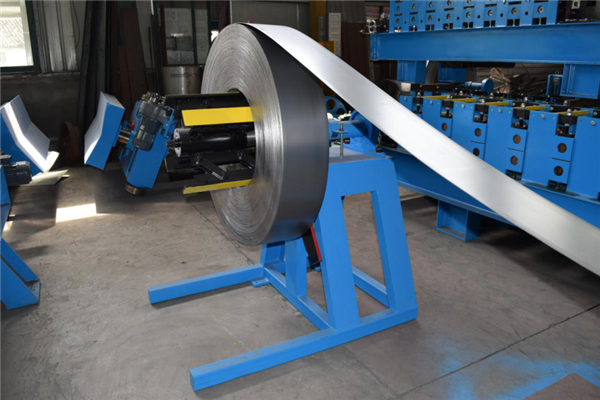

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

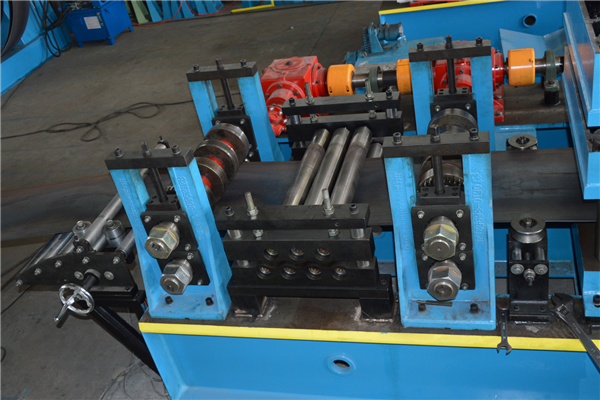

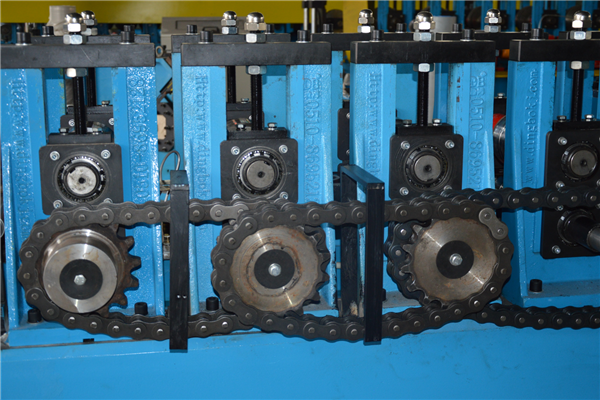

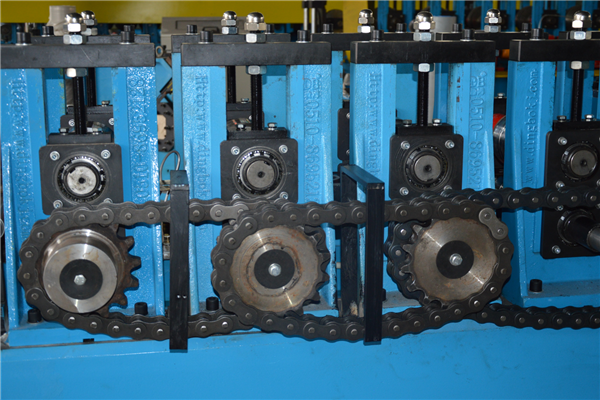

Driving system |

Chain drive |

Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

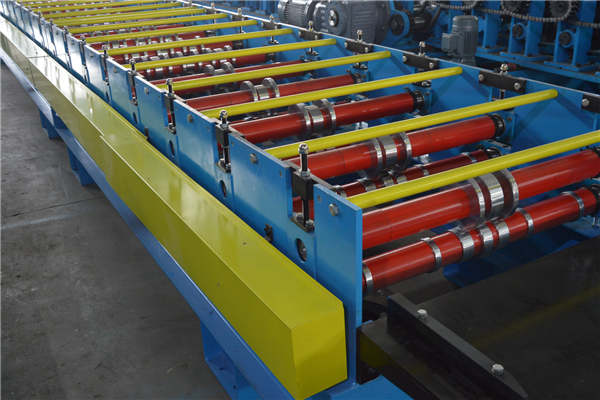

Station structure |

Wall panel station |

Forged Iron station |

|

Or torri stand structure |

|||

|

11 |

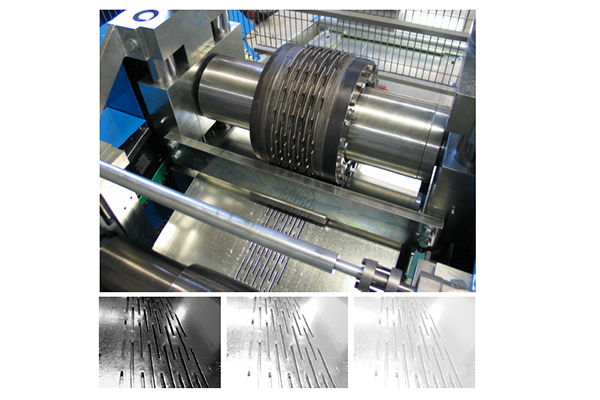

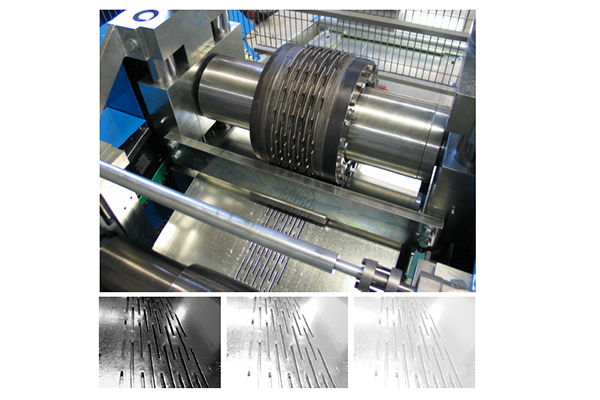

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

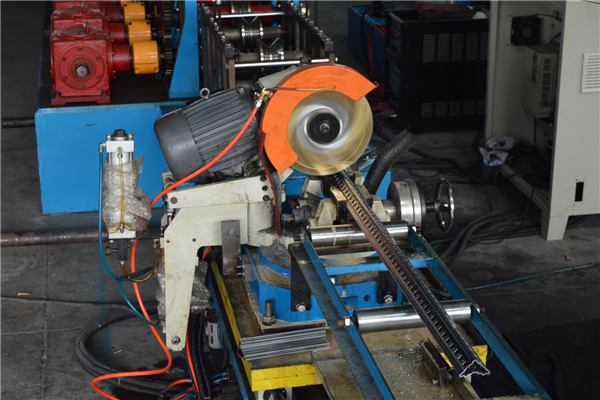

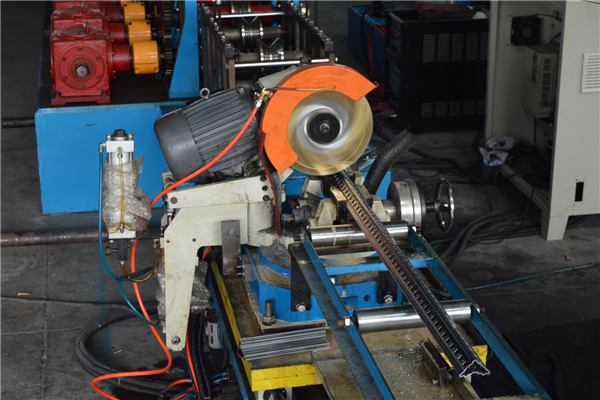

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 50Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

The door frame is one of the main contents of the home decoration, and it also connects the opening of the interior decoration material to make the craft more perfect. The door frame can also repair the door, the window frame is not sealed, and the air leaks in the decoration process.

-

Decoiler

-

Manual Decoiler

-

Hydraulic Decoiler

-

Double Head Decoiler

-

-

Feeding

-

Leveler

-

Servo Feeder

-

-

Punching

-

Punching Press

-

Hydraulic Punching Station

-

Rotary Punch

-

-

Stands

-

Wall Plate

-

Casting Iron

-

Guide Post

-

-

Driving

-

Chain Drive

-

Gearbox Drive

-

Gearbox Drive With Coupling

-

-

Cutting

-

Saw Cutting

-

Fast Flying Cutting

-

-

Out Table

-

Non-Powered

-

Auto-Stacker

-