DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

Email: sales@dingbokj.com

Tel: 8613921262246

The tube production machine/welded pipe roll forming machine is intended for manufacturing of high frequency straight seam welding tube , square tube and special shapes tube of Φ50.8mm-Φ127mm with thickness of 0.6mm-3.0mm.

The production line adopts advanced pass technology, PLC automatic control system, with stable operation, convenient operation and repair, and reached the advanced level in the same industry in the structure and accuracy.

Equipment from the material to tube run out, the speed adjusts according to the tube specification changing. This is tube and pipe roll forming automatic welding pipe production line.

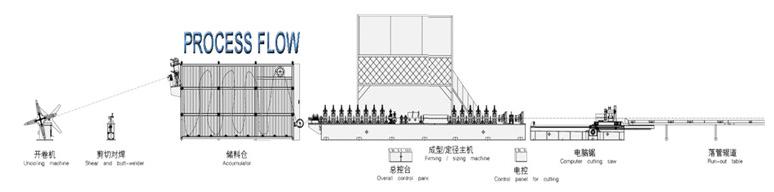

Working Flow

Slit Coil — Un-Coiler — Shearing And Butter Welder — Storage/ Accumulator — Forming — Welding — Cooling — Sizing — Cutting Saw — Run Out Table — Finishing — Pipe Collecting and Packaging

|

Raw material |

Hot rolled steel, cold rolled steel, galvanized steel |

|

Wall thickness Round tube |

0.6-3.0mm |

|

Square tube |

40×40-100×100 |

|

Width of strip steel |

160-400mm |

|

Tube welding speed |

20-100m/min |

|

High frequency welder |

300kW |

Machine Components

1. Decoiler

2. Shear and butter welder

3. Accumulator

4. Straighener

5. Forming machine

6. Welder and cleaner

7. Cooler

8. Size mill

9. Flying saw cutter

10.Run out table

|

Unit power standard |

380V / 22V; 50HZ; three-phase four-wire system |

|

|

Unit power |

high frequency |

300 KW |

|

Main motor |

220 KW |

|

|

Unit area |

45M×5M(L*W) |

|

|

High-frequency room volume |

5M×4M×2.8M |

|

|

Water source |

cooling pool 30m³ / 1 set high-pressure pump |

|

|

Air source |

1 set Air compressor |

|

|

Required lifting equipment |

Two 10-ton cranes |

|

|

Conventional consumables |

|

|

Tube mill is mainly used for producing pipes for furniture industry, construction industry, home appliances. The machine can produce round tube, square tube, rectangular tube, oval tube ect.

It also can produce half pipe, plum pipe and different shaped tube. Main applications including:

● Furniture industry: Steel table tubes, Steel chair tubes, Steel bed tubes, Steel towel racks, etc.

● Construction industry: Steel guardrail, steel door, steel handrail and steel window, etc.

● Public facility industry: Flagpoles, outdoor sports equipment, bus and metro handrails, etc.